- Home

- Special PLA 1.75mm

- eSUN ePLA Light Weight Filament 1.75mm 1kg - Various Color

eSUN ePLA Light Weight Filament 1.75mm 1kg - Various Color

Related Products

Bambu Lab PLA Aero Filament 1.75mm - 1kg (Various Colors)

$43.00

Bambu PLA Aero Bambu PLA Aero achieves low density and light weight by foaming at high temperatures during printing and creating small holes inside the prints. It's the perfect choice for light-weight and energy-saving prints, including unmanned aerial vehicles (UAVs), aerodynamic models, and gliders. Foaming PLA materials (PLA Aero) have high r...

Bambu Lab PLA Basic Gradient 1.75mm - 1kg (Various Colors)

$24.00

Soft Bicolor Gradient Appearance The soft transition between two colors creates a vibrant and stunning visual effect on printed models. Display of Gradient Prints Gradient colors make it ideal for printing pretty toys or decorations. High printing speed with delicate finish Up to 300mm/s (with 0.4mm nozzle) printing speed while maintaining delic...

Bambu Lab PLA Glow 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Glow 1.75mm - 1kg (Various Colors)

$24.00

Bambu PLA Glow PLA Glow stands out due to its incorporation of a unique additive: luminous powder. This variant retains the familiar qualities of traditional PLA, including easy printing, high quality, and exceptional overall mechanical properties. What sets PLA Glow apart is its distinctive feature - it glows in the dark. This makes it the op...

Bambu Lab PLA Marble Filament 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Marble Filament 1.75mm - 1kg (Various Colors)

$24.00

Bambu PLA Marble Bambu PLA Marble mimics the appearance of natural stone. With inorganic particles in its composition, it offers a vivid stone-like texture that resembles marble, granite, or bricks. It adds a touch of nature to your prints and provides a stunning finish for your projects. RFID for Intelligent Printing All printing parameters are...

Bambu Lab PLA Matte Filament 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Matte Filament 1.75mm - 1kg (Various Colors)

$22.00

BULK SALE PRICE RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through the AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 55 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, w...

Bambu Lab PLA Matte Refill 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Matte Refill 1.75mm - 1kg (Various Colors)

$19.00

BULK SALE PRICE RFID for Intelligent Printing All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps. Recommended Printing Settings Drying Settings (Blast Drying Oven) 55 °C,8 h Printing and Keeping Container's Humidity < 20% RH (Sealed, w...

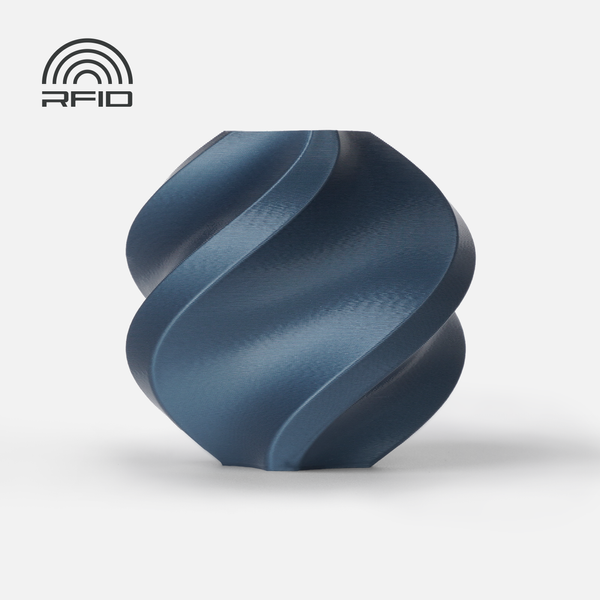

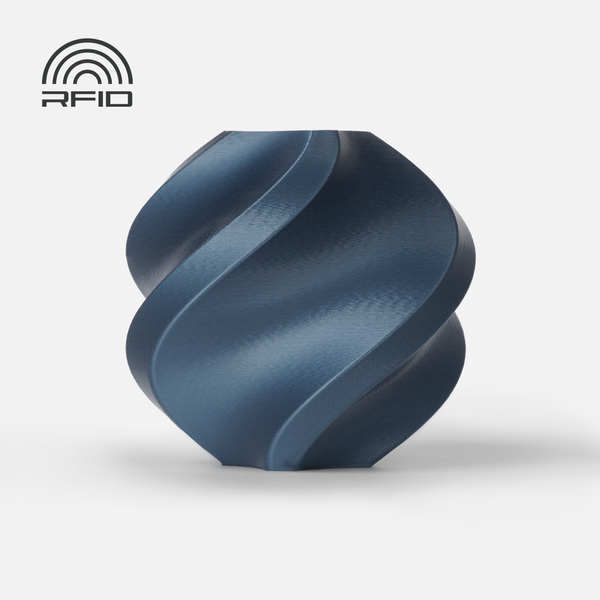

Bambu Lab PLA Metal Filament 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Metal Filament 1.75mm - 1kg (Various Colors)

$24.00

Bambu PLA Metal Bambu PLA Metal is a metallic textured filament designed to enhance the aesthetic of your prints. It is designed to mimic the surface texture of metal, but it does not contain actual metal fillers. With its advanced metallic shine, this filament offers a professional and high-end finish and a touch of sophistication to your print...

Bambu Lab PLA Silk Filament 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Silk Filament 1.75mm - 1kg (Various Colors)

$24.00

Bambu PLA Silk Bambu PLA Silk offers a silk-like and high-glossy that adds a luxury appearance to your prints while retaining PLA's ease of use. Different with other silk filaments, Bambu PLA Silk was toughened and demonstrates greater resistance to breakage when using AMS printing. It's ideal for decorations, artistic projects, and 3D character...

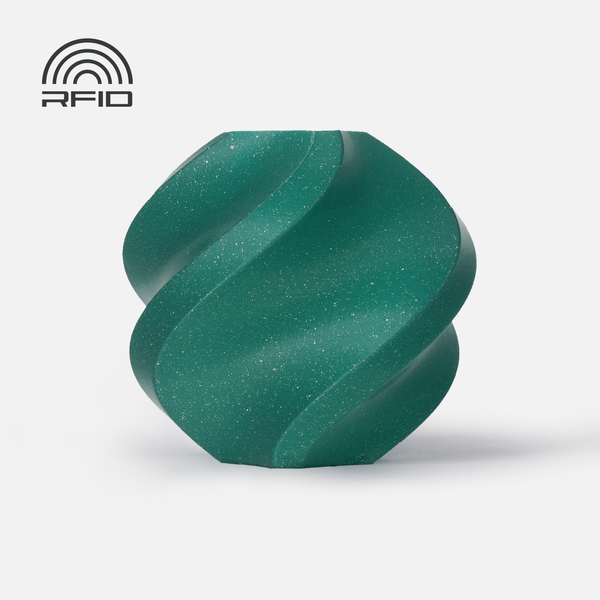

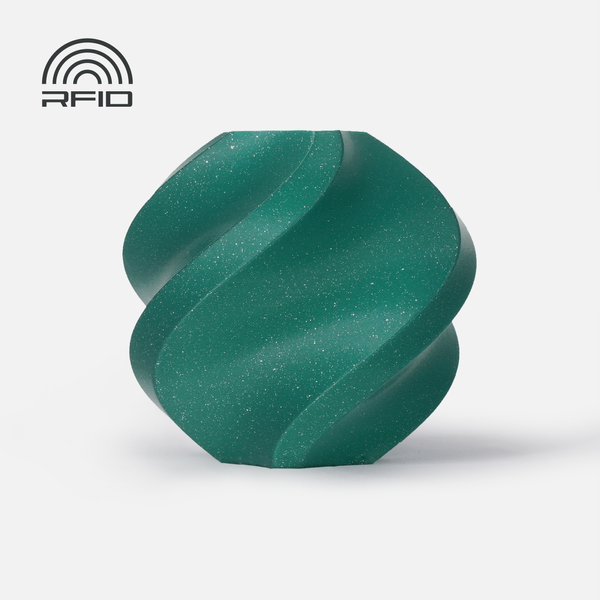

Bambu Lab PLA Sparkle 1.75mm - 1kg (Various Colors)

Bambu Lab PLA Sparkle 1.75mm - 1kg (Various Colors)

$24.00

Bambu PLA Sparkle Bambu PLA Sparkle is a next-level aesthetic filament that combines strength and sparkle. With metal particles included in its composition, Bambu PLA Sparkle adds a special sparkling look to your prints that sets them apart from the rest. However, it is not recommended to use a 0.2 mm nozzle for printing as clogging may occur. T...

Bambu Lab PLA-CF Filament 1.75mm - 1kg - Various Colors

$33.00

Carbon Fiber Reinforced PLA Bambu PLA-CF Bambu PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner-friendly like regular PLA. It is AMS compatible with low clogging risk at high-speed printing. The prints are in matte finish with almost invisible layer lines, which make it suitable fo...

colorFabb LW PLA - 1.75mm 750g (Various Colors)

$19.00

colorFabb LW-PLA Light weight PLA (LW-PLA) is the best filament for printing RC Planes, Cosplay and other light weight items. Parts are feather light, yet retain good strength and are easy to cut, trim and sand. If part weight matters to you, then this is your filament of choice. Pros Reduce the weight of printed parts up to 65% compared to re...

colorFabb Tough PLA - 1.75mm 750g (Various Colors)

colorFabb Tough PLA - 1.75mm 750g (Various Colors)

$11.00

colorFabb Tough PLA ColorFabb Tough PLA 3D printing filament features a better balance between material toughness and ease of 3D printing. The new formulation increases impact strength with 70% while retaining most of it’s tensile strength. Tough PLA can be printed at slightly higher temperatures then regular PLA for improved performance and e...